You’re in a building and you find you have to cut some concrete. Now unknown to you, your slab may look like this, before the concrete was poured

X-ray is the best way to pinpoint safe areas to penetrate slabs like the Post Tensioned one shown, which minimizes the risk of severing embedded items you may not want to sever, like a post tension cable for example.

At this time, x-ray is mainly being performed with radioactive isotopes, Iridium 192 and Cobalt 60. The workhorse of the industry, Iridium, is used for concrete that is 10 inches or less, while cobalt is for thicknesses up to 24 inches

Here is a list of things you need to do to help us make our service to you a safe and successful one

The first thing you need to do is consult with the Building Engineers and Building Manager about the upcoming event. You will need to set in place the following with the building for Concrete Imaging to do the service (let’s use an office building first, residential we’ll discuss a little later):

2nd – We need to know when the tenants and service personnel are all off the floors the penetration(s) are going through and are all off the floors the penetrations are coming out.

3rd – We’ll need to know how thick the concrete is, preferably before we mobilize so we can bring the proper device to do the service. With that, we also need to know the penetration sizes and the centers of the penetrations, on both the “top-side” and on the underside should be completed before the crew arrives. Some contractors drill “pilot holes” , CIM prefers to use a “Drill-Spotting” device to quickly locate the underside centers of penetrations. You can get one one made by Hilti at this link: https://www.hilti.com and look for the PX 10 Transpointer device

The “Top” center needs marked The “Underside” center marked also CIM uses a “Drill Spotting” Device

The “Top” center needs marked The “Underside” center marked also CIM uses a “Drill Spotting” Device

As we have transitioned over to digital radiography from film radiography, we no longer will need to put a darkroom in a loading dock for film processing has processing the imaging now is done near- real time, on the floor(s) where the penetrations are. However we will need to access it if we need to use the cobalt in order to safely get it in the building for radio-graphing the thicker concretes.

4th – Once we get on the site we review the work areas, post our signage then set up our equipment. During this period of posting signage and “taping off” access points, we will need access to all offices and suites on the floors in order for the technicians to physically check to make sure those areas are empty of the “General Public” and if not needed to be entered during the service, they can then be locked back up.

The traditional way of providing this service has been using “medical” x-ray film (which is a strange way to relate to the film as it is designed for use in industrial applications) and 2 key types of radioactive isotopes to emit a collimated gamma beam, at a fixed projection angle, for a calculated amount of time to expose the piece of film.

CIM no longer uses this method as our environment for providing this service is changing, basically they are building buildings closer together and are using glass facades instead of stone/ masonry facades. So to adapt to this ever changing environment, we had to reduce our overall radiation signature and emissions enough to be able to safely perform this work in buildings in our nation’s capital and the surrounding areas in which we perform our services.

In able for us to accomplish this, we invested into Digital CCD technology, which is around 90% more efficient than traditional film radiography and has many benefits over the older method.

With the digital system, we email the results to whoever wants them and for many projects, we give the client a “jump stick” with the .jpg and .tiff files from the exposures on it. At the bottom of this page is a link for a free download for viewing software for the image files from that jump stick. When we email the images, they are put in report form with the images marked up showing conflicts and other information.

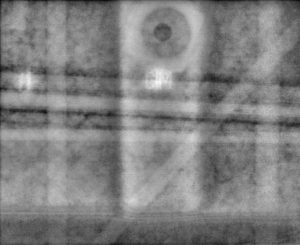

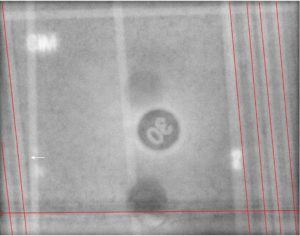

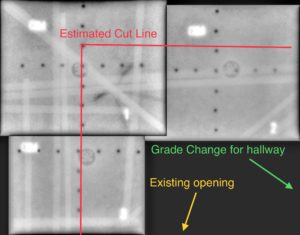

Here are some samples of the digital radiographs from a recent project:

These two images are the raw images before we mark them up and put them on a report document

The images below, we have highlighted the embedded conflicts that were noted along with additional information with the image which we put on a document (either a PDF or WORD document).

With CCD technology, the results are near real-time and we mark the slab at that time. The advantage of this is within a few minutes, we can tell if a location will not work and if we need to move over a little bit for a clear path. We then simply re-adjust the set-up and take another exposure.

With this service, we offer a limited damage free warranty for digital radiographic imaging and below is the verbaige found on line item #6 of our “General Conditions” which explains our stand with the imaging services we offer:

CIM provides a limited warranty on concrete radiographic testing services and this limited warranty covers only items severed within the concrete (that initially were to be avoided) due to cutting operations after CIM has completed the radiographic testing services. No other warranty is expressed or implied, is made or intended by CIM. This warranty only covers the review, repair or replacement of the item that was damaged and/or the necessary additional services required for its review, repair or replacement. However, CIM will set forth parameters and limits for cutting, and if the parameters and limits are found to have been exceeded, CIM is then, with all extent and purpose, held harmless and any and all warranties are then null and void. CIM will use that degree of care and skill ordinarily exercised under similar conditions by reputable members of our profession practicing in the same or similar locality. The extent of CIM’s liability will be a total sum equal to the individual shift invoice amount. CIM offers NO Warranty expressed or implied or intended with Ground Penetrating Radar Technology.

Our General Conditions are copied on the reverse side of our work-orders and are included with every formal price quote given out.

As mentioned earlier, services to be performed in residential buildings require a lot of tenant coordination, cooperation and timing to accomplish a safe and successful imaging service. It is recommended we perform a site safety analysis, meet with management and make a “game plan” that offers minimal impact to the tenants while being able to get the service completed quickly. Depending on where the work is in buildings, we may be able to complete the work off-hours as normal or may need to make a special daytime shift schedule.

Let’s say you find your concrete thickness is greater than 10 inches, the threshold of Iridium 192 has been reached and a stronger isotope is then needed to provide an image. Cobalt 60, whose limitations is close to 24 inches thick is the device needed for thicker concretes.

Cobalt has certain requirements that are necessary to have due to the size, weight and radiation emissions of the device. The device for one weighs just under 1,000 pounds and is 35.5 inches wide by just under 4 feet long and around 42 inches high (due to the handle attachment).

Cobalt and Iridium devices

It cannot be carried up steps, but must be hoisted or lifted to the area it needs to go if not at the ground level or if an elevator is not available. With the advantage of no longer needing a darkroom to process film, we can fit into garages that can accept a full-size pick-up with a cap, towing a trailer if necessary to get into buildings. This is advantageous when we have jobs where the P-1 level IS the underside.

The device has both pneumatic and non-marring tires, although CIM would prefer floor protection in place, has been pushed across stone lobbies and such before with no damage.

Cobalt 60 emits 2 gamma rays thus making it roughly 3 times stronger than Iridium 192 with the ability to penetrate thick concrete. With CIM using a Cobalt isotope with Digital CCD Technology, this greatly reduces the exposure times compared to our competitors. With this though, our devices emit rather high amounts of radiation and our restricted areas are larger, but the exposure times are greatly reduced, thus reducing our overall radiation signature.

CIM standard requirements for areas of where operations are to be conducted require those areas, on both the top (film) side and the under (device) side to be totally vacant of persons. Please consult with our Radiation Safety Officer as to job/site specific conditions and requirements.

If you have any questions, please contact us

Site Preparation for Efficient Service- What you can do to save $$$

Understanding Digital Radiography-How we read the results