High Definition Ground Penetrating Radar (GPR) uses an electromagnetic energy pulse to locate embedded items in concrete slabs and surfaces. With this technology, the technician scans the concrete surface, which transfers the energy into the slab. The energy comes in contact with the embedded items and transmits a response back. The technician then reviews the data to determine which items are in the slab and records the information on the slab via a layout. Because Ground Penetrating Radar (GPR) is in direct contact with the concrete, this technology is considered noninvasive and safe to be around. GPR can be used in occupied buildings, like hospitals and hotels.

Below are examples of data collected using real time line scanning by Concrete Imaging GPR technicians.

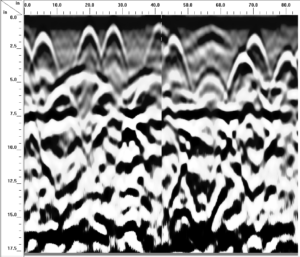

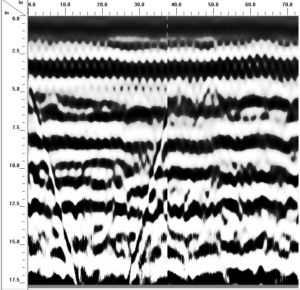

2D Linescan Raw Data – This is the data our techs are trained to read, we’ve found to be more accurate than 3D

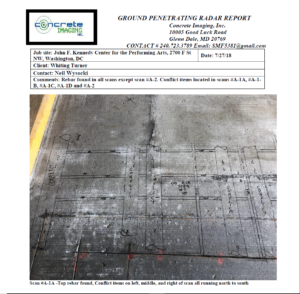

Here’s a 2D Linescan with a conflict item in between the top rebar and the bottom rebar. CIM”s philosophy with respect to embedded conflict items is, we first locate and map out the rebar grid. Rebar, when placed in concrete has tendency to stay about the same plane, you can figure maybe a bar thickness deviation, but it basically becomes a constant. Anything noted that is in between grids, angled to grids, different return signature than the grid signatures, things like that, we regard it as a conflict. Our technicians will not confirm the identity of the item noted, only note it and make you aware where we believe the target is, the direction and depth as per the display rendered from the survey equipment. We magnify these items when we draw out the rendering on the slab to give you a safety boundary, however, if you have to go there or near there, we highly recommend an x-ray be performed, if possible to confirm whether or not you will have a safe path to penetrate.

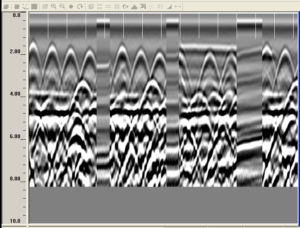

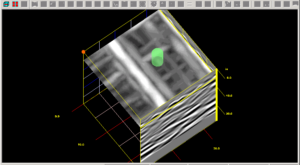

3D GPR scan – Some equipment requires the use of a bar coded grid, some have on-board grid patterns that are set with an “axis” and scan pattern for the operator to use. We have found this method to be less accurate in many types of situations than a 2D Linescan as the machine’s small on-board computer renders the image displayed. The image file can be “jumped” from the machine and examined with more powerful software, however that takes a lot of time, much less production and your cost is getting close if not exceeding an x-ray, which is guaranteed to a degree. Many times, with close spaced items in the upper portions, the lower items will not be seen at all, no matter how fine you slice the image, whereas 2D Linescanning the lower objects may be seen.

Here is a sample of the reports we email out within 24 hours of the service:

CIM uses several different versions for GPR from the same manufacturer, Geophysical Survey Systems, Inc

One is the MiniXT which is a high-definition machine with a 20 inch depth rating

Our newest additions are the SIR4000 High Definition systems which we use on high production projects

And of course our older, trusty SIR 3000 systems

Here’s our Field Operations Manager, Corey busy scanning a wall.

And has CIM usually has a 2-man team on practically all of our projects, while one tech is scanning, the other is “laying-out” the scan and documenting the scan for verification. This helps increase our production values per shift.

Due to varying degrees of inaccuracies with this equipment, which are much smaller than the earlier units had, from extrapolation of file data during processing, “ringing” returns (this is where metal targets are closer together, around 4 inches and less and the return result basically “masks” items below as shown here) and surface conditions,

please note, Concrete Imaging does NOT offer any type of warranty, either expressed, implied, conveyed, intended or otherwise with this technology. As an assurance, CIM will use that degree of care and skill ordinarily exercised under similar conditions by reputable members of our profession practicing in the same or similar locality. Our goal is to provide to you, our customer, with answers to questions regarding objects that may be embedded below the surface area and the prominently of these objects. Our customers must understand that our findings are an interpretation of what we view from the rendering of the survey equipment. These findings have been performed with use of the latest technology the industry has to offer, specifically designed for this work through fully trained operators, in order to provide the most accurate readings. After we provide the interpretation, the decision to proceed further with cutting is entirely that of the Customer.